Venturi / Fluid Jet

KORTING Fluid Jet Equipment is a group of products most of which operate on the Ejector or Jet Pump principle with no moving parts which can be used to pump, mix, heat, cool or produce a vacuum using a high pressure/velocity motive fluid to entrain a lower pressure suction fluid.

How it works

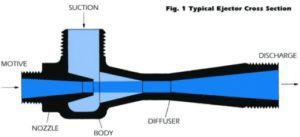

An ejector comprises three key parts – nozzle, diffuser and the body as per this diagram of a typical Venturi fluid jet product.

The driving fluid or motive (steam, pressurised liquid or air) passes through the nozzle of the ejector, converting the pressure energy into a jet. The result of this is that the fluid at the front of the jet is displaced, producing an area of low pressure at the exit of the nozzle.

Both the motive and the suction fluid must be compatible and the two coming together allow one ejector to perform two operations, for example pumping and mixing.

Fluid jet products from Northvale Korting are available as individual items or packaged modules with other relevant products such as control valves and pumps.

Applications by Industry Type

For further details of how KORTING Fluid Jet Equipment can be used, click on an application below which best matches your requirement. Select your industry type to see the relevant applications.

Biogas

Blending and Mixing

Brewing

Entrainment of Powders

Gas Cleaning

Nuclear

Paper Production

Pharmaceutical

Power Plants

Pumping Solids

Ship Building

Waste Treatment

Water Treatment

Aeration & Gas Entrainment

Liquid Jet Exhausters can be used to continuously entrain air or gas to aerate or promote gas/liquid contact. Alternatively a variant of a Tank Mixing Eductor can be used for the same purpose inside a tank.

Agitating & Mixing Tank Liquids

By using an existing transfer pump to recirculate tank liquids through a Tank Mixing Eductor the whole tank contents can be mixed and agitated to avoid stratification, keep solids in suspension and produce uniformity of temperature, pH etc.

Bilge Emptying

Liquid Jet Eductors or Steam Jet Syphons are ideal for bilge emptying because of their attributes of being self-priming, capable of handling solids, will run dry without detriment and having no moving parts, require no regular maintenance.

Blending Tank Liquids

Where a secondary batch of liquid has to be added to, and thoroughly blended with, the liquid contents of a tank, the secondary liquid can be introduced as the motive liquid of a Tank Mixing Eductor. Depending on batch proportions, this can produce a thoroughly blended liquid in the time it takes to add the secondary liquid.

Bund & Pit Emptying

Open bunds and pits can fill with rainwater and need occasional emptying. In addition to the attributes given under Bilge emptying, Liquid Jet Eductors and Steam Jet Syphons are very suitable for installation in hazardous zones.

Creating Process Vacuum

Liquid Jet Exhausters, Steam Jet Ejectors and Gas Jet Ejectorscan also be used to create vacuum and entrain vapours from a process on a continuous handling basis.

Direct Contact Condensing of Steam/Air Mixtures

Condensation of waste steam or air/steam mixtures can be carried out by spraying low pressure cooling water into a Direct Contact Condenser. Vacuum operation is also possible.

Direct Steam Injection Heating of Liquids in Pipelines

Under some circumstances it may be beneficial to heat liquids in pipelines by direct injection of steam into liquid. This can be done quietly using either an Instantaneous Heater or an Ejector Heater. Benefits include full utilisation of available enthalpy, no condensate to handle and smaller space envelope than a heat exchanger.

Direct Steam Injection Heating of Liquids in Vessels

As per Direct steam injection heating of liquids in pipelines, except the heating takes place inside a vessel with a Circulating Heater or in an external loop with an Ejector Heater. Positive circulation within the tank is assured.

Priming & Start-up Evacuation

Liquid Jet Exhausters, Steam Jet Ejectors and Gas Jet Ejectors are used to entrain a gas and thus create a vacuum in a closed system. This type of duty includes pump priming and evacuation, prior to start-up, of process systems such as distillation columns.

Pumping & Diluting Concentrates

This is a specific example of Pumping Liquids but can only be done with a Liquid Jet Eductor. Usually specified to achieve a certain discharge flow at the required dilution rate. Pumping of concentrates can also use a small Liquid Jet Eductor in a round the pump loop.

Pumping Liquids

By using a liquid or steam under pressure as a driving medium a Liquid Jet Eductor or a Steam Jet Syphon can be used suck in another liquid at negative pressure and discharge the total flow against a higher pressure.

Pumping Solids & Slurries

Liquid Jet Eductors can also be used to pump solids and slurries such as granular activated carbon, sand, ion exchange resin, lime and many other solids and powders.

Ship Deballasting

Use Liquid Jet Eductors driven by existing seawater pumps to assist emptying of ballast tanks.

Steam Desuperheating

Steam is often generated at pressures and temperatures higher than needed for some processes. Condensate can be atomised by various methods in a Desuperheater to reduce the steam temperature.

Product Range Liquid

- Jet Pumps

- Steam Ejectors

- Mixing Educators

- Steam Desuperheaters

- Direct Contact Condensers

- Powder & Granule Eductors

- Tank Circulating Heaters

- Steam Heaters

Materials

- Cast Iron

- Cast Steel

- Bronze

- Stainless Steel

- UPVC and non-metallic linings

Contact us with any enquiries and we will be happy to help.